OBJECTIVE of PQ for RLAF (Reverse Laminar Air Flow)

To determine that the PQ for RLAF (Reverse Laminar Air Flow) perform as intended by repeatedly running the system on its intended schedules and recording all relevant information and data. Results must demonstrate that it consistently meets pre-determined specifications under normal condition, and where appropriate the worst-case situations.

To verify that the equipment operates in accordance with the design and user requirements asdefined by set Acceptance Criteria and complies with relevant cGMP Requirements.

To verify the Performance features of Reverse Laminar Air Flow and to ensure that it produces desired Quality & rated output according to manufactures specifications.

To verify all the performance features from user point of view of the Equipment

TABLE OF CONTENT

| PARTICULARS | PAGE NO. |

| Title page | |

| Table of content | |

| Objective | |

| Scope | |

| Qualification Schedule | |

| Location of Equipment | |

| Validation Team and Responsibility | |

| Pre-approval of documents | |

| Scope of supply | |

| Brief process description | |

| Performance qualification procedure | |

| Performance verification | |

| Performance qualification report | |

| References | |

| Result | |

| Deviation/change control | |

| Summary | |

| Conclusion | |

| Recommendations | |

| Attachments | |

| Post approvals |

SCOPE

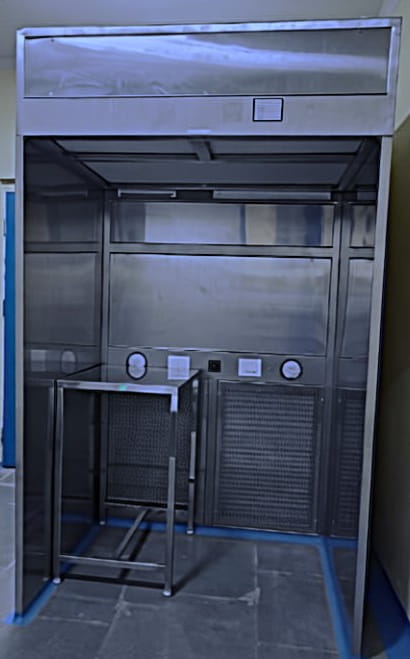

The scope of this Performance qualification protocol is limited to qualification of Sampling Booth (Reverse Laminar Air Flow) installed in Packing Material Sampling Area.

This Protocol will define the methods and documentation used to perform PQ activity the Sampling Booth (Reverse Laminar Air Flow) for OQ. Successful completion of this Protocol will verify that Reverse Laminar Air Flow meet all acceptance criteria & ready for daily activities

This document is applicable for Sampling Booth (Reverse Laminar Air flow)located at premises.

QUALIFICATION SCHEDULE

Frequency

Performance check of the machine should be re-qualified after every 5years ±2 months.

LOCATION OF EQUIPMENT

The location of the equipment is in Approved PPM store

| Name of Equipment | ID No. | Room Name | Section |

| Sampling Booth | Primary packing material sampling Area | Quality Control |

VALIDATION TEAM AND RESPONSIBILITY

| Department | Responsibility |

| Engineering | v Preparation of protocol and compilation of report. v Review ofprotocol and report. v Execution of Qualification activities with the user/ concern departments per the protocol. v Responsible for the compliance of qualification data |

| Warehouse | v Review of protocol and report. v Execution of qualification activities as per the protocol |

| Quality Control | v Review of protocol and report. v Execution of qualification activities as per the protocol |

| Quality Assurance | v Review, approval and certification of the protocol / reports. v Execution& approved of qualification activities as per the protocol& certification after successful qualification of equipment. v Responsible for the compliance of qualification data |

PRE APPROVAL OF DOCUMENTS of PQ for RLAF (Reverse Laminar Air Flow)

Prepared by

| Designation | Name | Date | Signature |

| Executive/Officer Engineering |

Checked By

| Designation | Name | Date | Signature |

| Head Engineering | |||

| Head Warehouse | |||

| Head Quality Control |

Approved by

| Designation | Name | Date | Signature |

| Head QA |

Scope Of Supply:

| Description | Specification |

| Make | |

| Model | GMP |

| Serial No. | |

| Control system | 220 volts, Single phase power supply |

Brief Process Description:

- Reverse Laminar Air Flow (RLAF) is a specialized air handling system used in the pharmaceutical industry to maintain a controlled and contaminant-free environment. By directing airflow from a contaminated area towards a clean area, RLAF prevents the introduction of contaminants into critical zones, ensuring the safety and quality of pharmaceutical products. Reverse Laminar Air Flow (RLAF), or Reverse Laminar Flow (RLAF), is a specialized air handling system used in pharmaceutical and clean room environments. It is designed to maintain a controlled environment by preventing the contamination of sensitive products, equipment, or processes.

- Unlike traditional laminar airflow systems, where the air flows from a clean area toward a contaminated area, RLAF operates in the opposite direction. The air flows from a contaminated area towards a clean area, minimizing the risk of contaminant introduction

- The working principle of Reverse Laminar Air Flow (RLAF) involves the controlled direction of airflow from a contaminated area towards a clean area, ensuring that contaminants are contained and prevented from reaching critical zones. Here’s a breakdown of the working principle:

PQ for RLAF (Reverse Laminar Air Flow) PROCEDURE

- The Operation Qualification status of the instrument was checked and the execution was started only after completion of operational qualification report.

- Availability of calibration certificates of all the attached instruments shall be checked.

- The power supply and connected utility shall be checked before starting Performance Qualification.

- The operating functions of control panel switches and buttons shall be checked.

- The motor functioning test shall be performed.

- No Deviation should be observed during Performance Qualification.

PERFORMANCE VERIFICATION

Objective of this performance verification is to provide documented evidence that equipment performs as per respective and up to its operating & performance range.

Standard Operating Parameters Verification

To verify the standards operating procedure required in the qualification of sampling booth shall be of current version.

Calibration of all measuring Instruments

Verify the calibration of all the measuring instruments used during qualification of sampling booth, as mentioned below.

| Item Description |

| Anemometer |

| Particle count |

| Aerosol Photometer |

Observations & Results

Ensure calibration of the instruments used to test validation parameters during qualification of Sampling booth are in valid period& record the calibration details in Annexure–I

Annexure-I

| Sr. No. | Instrument Name | ID no. | Calibrated on | Calibration due on | Calibration report No. |

Checked By (Sign & Date):__________________

PROCEDURE FOR AIR VELOCITY MEASUREMENT

Ensure that the Supply blower of the Equipment containing HEPA filter is “ON” prior to the start of the observations

Ensure that the instrument (vane or hot wire anemometer or flow hood with flow meter) is having a valid calibration certificate.

Measure the air velocity (FPM) at five different locations of the supply air grill at a distance of about 150mm (6”) as shown below:

| B C E A D |

Read Also :- OQ of RLAF

The measuring time at each location should be at least 10 seconds and average reading should be taken

Record the reading in the raw data format of external agency and attach the same

Calculate the average velocity of the air coming from Supply Grill as per the following formula Average air velocity (FPM) = Readings of (A + B + C + D + E) 5

Acceptance Criteria:

Average measured clean air cross sectional velocity under the absolute terminal/filter module should be 70- 110 FPM and /or more depending upon the filter size. Filter area and / or rated velocity across the filter, when measured about 6 inches downstream of the subjected filters.

PROCEDURE FOR MONITORING THE NON-VIABLE PARTICLECOUNT TEST:

For Grade D areas sample shall be taken for one minute time and the volume drawnshall be 28.34 liters (1CFM). The data of cumulative particle counts 0.5 and 5m shall be recorded

For Grade A, B & C areas the sample volume shall not be less than 1000 liters (1m3). The data of cumulative particle counts 0.5 and 5m shall be recorded

Where only one location is required to be sampled, take minimum of three single

Sample volumes (3 cycles), with delay time not more than 10 seconds at that location and compute the average particle concentration.

When the number of locations sampled in the room is two to nine, compute the overall Mean of the averages, standard deviation and 95% upper confidence limit from the average particle concentrations for all locations

Note: When there is only one, or more than nine locations sampled, computation of 95 % UCL will not be applicable

Maximum concentration limits (particles/m3 of air) for particles equal to and larger than the considered particle sizes are given below:

Ensure that the area is clean.

Switch ON the equipment at least half an hour prior to starting the airborne particle counting.

Ensure the airborne particle counter is having a valid calibration certificate.

Set up the particle counter.

The sample probe shall be positioned pointing to the air flow. If the direction of the air is non unidirectional, the inlet of the sample probe shall be directed vertically upward.

In Grade D zone take the airborne particle counts (1CFM) as per the pre-determined locations at working height.

In Grade A, B & C zone sample 1 m3 of air as per the predetermined locations at a distance not more than 1foot away from the work site, within the airflow at rest and in operation.

The print out of the particle count shall be checked and the same shall be duly signed and filed along with a photocopy. The details of the particle count taken shall be entered in the format of external agency and attach the same.

The clean room is deemed to have met the specified air cleanliness classification if the average of the particle concentration measured at each of the location and when applicable, the 95% UCL, do not exceed the concentration limits (for 0.5 and 5.0 micron)

Acceptance criteria

| Acceptance Criteria Cleanliness class in Operation | Maximum permitted number of particles /m3 in operation | ||

| ISO | USFDA | 0.5mm | 5.0 mm |

| ISO Class 5 | Class100 | 3,520 | 29 |

| ISO Class 6 | Class 1,000 | 35,200 | 293 |

| ISO Class 7 | Class 10,000 | 352,000 | 2,930 |

| ISO Class 8 | Class 100,000 | 3,520,000 | 29,300 |

| ISO Class 9 | Not specified | 35,200,000 | 293,000 |

| EU Grade | Maximum permitted number of particles/m3 equal to or above | |||

| at rest | in operation | |||

| 0.5 mm | 5mm | 0.5mm | 0.5 mm | |

| A | 3 500 | 0 | 3 500 | 20 |

| B | 3 500 | 0 | 350 000 | 2 900 |

| C | 350 000 | 2 000 | 3 500 000 | 29 000 |

| D | 3 500 000 | 20 000 | Not defined | Not defined |

PROCEDURE FOR AIRFLOW PATTERN TESTING

Switch on the AHU / LAF / Equipment containing HEPA filter and hold the smoke generator near the supply air grill / diffuser. The fumes shall show the path of the air flowing from the supply air grill / diffuser

Hold the smoke generator near at the return air grill / diffuser / riser. The fumes shall show the path of the air flowing towards the return air grill / diffuser /riser

Airflow pattern testing shall be carried out for AHU / LAF / Equipment containing HEPA filters.

Acceptance Criteria

Air Flow Should be Linear & Direction of flow should be from supply grill towards Return

Grill

PROCEDURE FOR FILTER INTEGRITY TESTING

Filter testing shall be performed only after operational air velocities have been verified

Ensure that the Supply blower of the AHU / LAF / Equipment containing HEPA filter is “ON” prior to the start of the observations.

Ensure that the aerosol photometer is having a valid calibration certificate. The aerosol photometer should have a sampling rate not less than 28 L/min. (1 CFM).

Add Poly –alpha olefin (PAO) or suitable aerosol material recommended by the supplier to the aerosol generator.

Keep the aerosol generator near the return air grill / riser / fresh air damper of the AHU/ LAF / Equipment containing HEPA filter.

Provide compressed air or Nitrogen to the aerosol generator at the pressure of about 20 PSI (equivalent to 1.4 kg/cm2) and visually confirm the generation of aerosol.

Switch ON the Aerosol photometer and set the upstream concentration to 100 % to downstream.

The photometer probe should scan the entire filter face and frame at a position of approximate 3cm from the face of the filter and should be traversed slowly, using slightly overlapping strokes, as shown below (Step 2).

The entire downstream face of each HEPA filter, the perimeter of each filter and the seal between the filter frame shall be scanned once, as shown below (Step 1 & 2)

STEP 1: Scanning of perimeter of HEPA filter & joint between the filter frame and housing.

STEP 2: Scanning of HEPA filter media using slightly overlapping strokes

After completion of testing, the results shall be entered in the respective format report of external agency and attach the same.

Note: Remove the diffuser / grill in case of terminally mounted filter

Acceptance Criteria

- The leakage should not be more than 0.01% of the upstream concentration

- If the leakage from the flange joints is greater than 0.01%, repair it either by tightening the nuts or by applying the silicone sealant and repeat the test. (The area of single leakage shall not be greater than 1% of the total area, and the area of all leakage shall not be greater than 5% of the total area, otherwise, it must be replaced).

- If downstream concentration observed from the filter media is more than the acceptable limit. (20 to 80 mg/m3)

- Scanning rate should not be less than 8cm/s

PERFORMANCE QUALIFICATION REPORT:

_________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

REFERENCES:

HVAC validation & Revalidation

RESULT:

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Written By (Sign & date):________________

DEVIATION/CHANGE CONTROL

____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Checked By (Sign & date):________________

SUMMARY:

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Written By (Sign & date):________________

CONCLUSION:

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Written By (Sign & date): ________________

RECOMMENDATIONS

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Written By (Sign & date):________________

ATTACHMENTS:

| Document name | Reference No. | Checked by Sign& Date |

POST APPROVAL OF DOCUMENTS

Prepared by

| Designation | Name | Date | Signature |

| Executive/Officer Engineering |

Checked By

| Designation | Name | Date | Signature |

| Head Engineering | |||

| Head Warehouse | |||

| Head Quality Control |

Approved by

| Designation | Name | Date | Signature |

| Head QA |