Objective of URS for Sonicator:

This document is generating under the authority of the company for the purpose of specifying the user requirement for Sonicator. The URS for Sonicator is provided to define the important components, variables and options necessary for the Supplier to provide a functional of sonicator that meets the needs in the most cost-effective method possible. The URS is also provided to the Supplier to provide a price quote for the supply for sonicator including the design, Performance and manufacture of the equipment.

This URS is an integral part of the procurement agreement with the Supplier.

Approval of Documents:

Prepared by:-

| Name | Designation/Department | Signature | Date |

Reviewed by:-

| Name | Designation/Department | Signature | Date |

Approved by:-

| Name | Designation/Department | Signature | Date |

Scope:

The scope of this document is to define the requirements of the sonicator in Quality Control lab of company.

Location of equipment:

Machine will be installed in the Quality control department of company

Communication:

References

The supplier shall use the following references in all communications: –

Applicable Codes and Standards: –

- The entire Supplier’s work shall comply with all relevant Indian and International Standards and Codes of Practice.

- The Supplier shall confirm all the Standards which have been used for the design and manufacture of the equipment.

System/equipment/Instruments details:

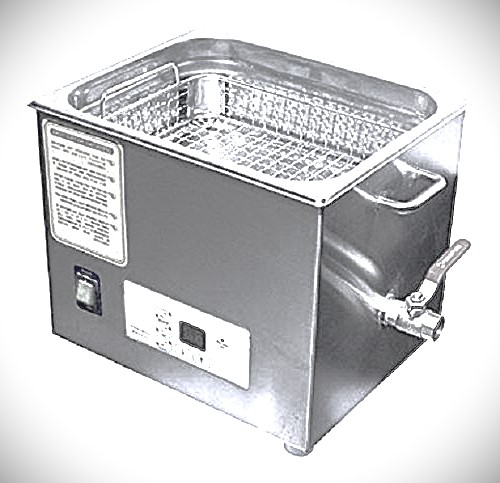

| Name of the equipment | Sonicator |

| Technical Specification | 21 CFR |

| Model/Type | As per GMP model |

Scope of Supply:

| Type of Device | Sonicator |

| Machine Standard | The current state of the art GMP Compliance. |

| Machine design standard for safety | ISO 13850:1996 safety of machinery- Emergency stops principle of design.ISO 14110:1998 safety of machinery- interlocking device associated with guards- principles for design & selection. |

| Room Condition | Room Temperature: – As per standardRelative humidity: – As per Standard |

| Features | Design conforming to cGMP standards. |

| Document & Certificate | Manuals and Maintenance Instructions Operator manualInstallation and assembly instructions for all devices.User’s manuals for all components.Trouble shooting guide.Maintenance Manual.Safety instruction.Training documentation. Electrical and Control diagrams Single line drawing for electrical distribution.Circuit diagramsCable list.Equipment location drawing for electrical equipment and instruments. |

| Qualification Protocols | IQ Protocol and reportOQ Protocol and reportPQ Protocol and reportVendor should organize for Execution of IQ, OQ and support for PQ |

| Training | Vendor should impart necessary Operational training to user department and maintenance training to maintenance department. |

| Test, Calibration, MOC Certification | All test certificate for brought items will be provides during FAT with FAT DocumentsMOC Certificate will be providing during FAT with FAT documentsCalibration certificate provide for gauge during FAT. |

Read Also :- Installation Qualification of Sampling Booth

Brief system description:

- A sonicator is an automated device used to dissolving the solutions prepared in Quality control lab for testing purpose.

- Function:

Sonicators can break down and disperse particles, which is useful in nano technology. .

- Chiller/Cooling system:

Since sonication generates significant heat, cooling coils or recirculating chillers are used to maintain a stable temperature for sensitive samples.

- Sound enclosure:

A box that minimizes the loud, irritating noise generated by high-intensity Sonication.

- Industries:

Sonicator are used in diverse industries like pharmaceuticals, Laboratories etc.

Technical Specification of URS for Sonicator:

| Sr. No. | Particulars | Specification |

| Tank Size | (LXWXH) mm | |

| Capacity | ||

| Time Setting | ||

| Heating Temperature | ||

| Display | LED | |

| Power Supply | AC 220V | |

| Lid Material | SS 304 | |

| Electric panel | Electrical panel with push button and digital indicator.Emergency Switch.On/ off switchElectric panel with MCB, contactor, overload relay, controls relay, temperature controller | |

| Utility Requirement | 220 W40 KHz | |

| Identification | Details of Make, Name, Serial.No., Capacity, Model and Year of manufacture should be available. |

Safety Features:

| Critical Variables | Acceptance Criteria | Reference |

| Metal Parts | All the metal parts should be properly grounded without any sharp Edges. | User Manual |

| Leveling and Balancing | Equipment should be properly balanced & leveled. | User Manual |

| Installation | All the Installation must be in accordance with the GMP. | User Manual |

| Electrical Wiring And Earthing | Electrical wiring should be as per approved drawings. Double external Earthing to control machine (panel and motors) and operator should be provided. | User Manual |

| Noise Level | Below 80 db. | User Manual |

| Emergency/Safety Switch | Provided easy access position | User Manual |

List of Abbreviations.

| URS | User Requirement Specification |

| ENG | Engineering |

| MOC | Management of change |

| FAT | Factory Acceptance Test |

| QA | Quality Assurance |

| cGMP | Current Good manufacturing |

| Ltr | Litre |